Irrigation uniformity and hydrogen peroxide

Added on 14 December 2022

Biofilm as a breeding ground

Ideally, you would use 100 percent clean water in your cultivation, but unfortunately that’s not realistic. You may get your water from a well, from a wastewater treatment plant, or by reusing irrigation water. That water probably contains a small quantity of microorganisms like bacteria and algae spores. When those come into contact with the inside of your irrigation system, biofilm will accumulate.[1]

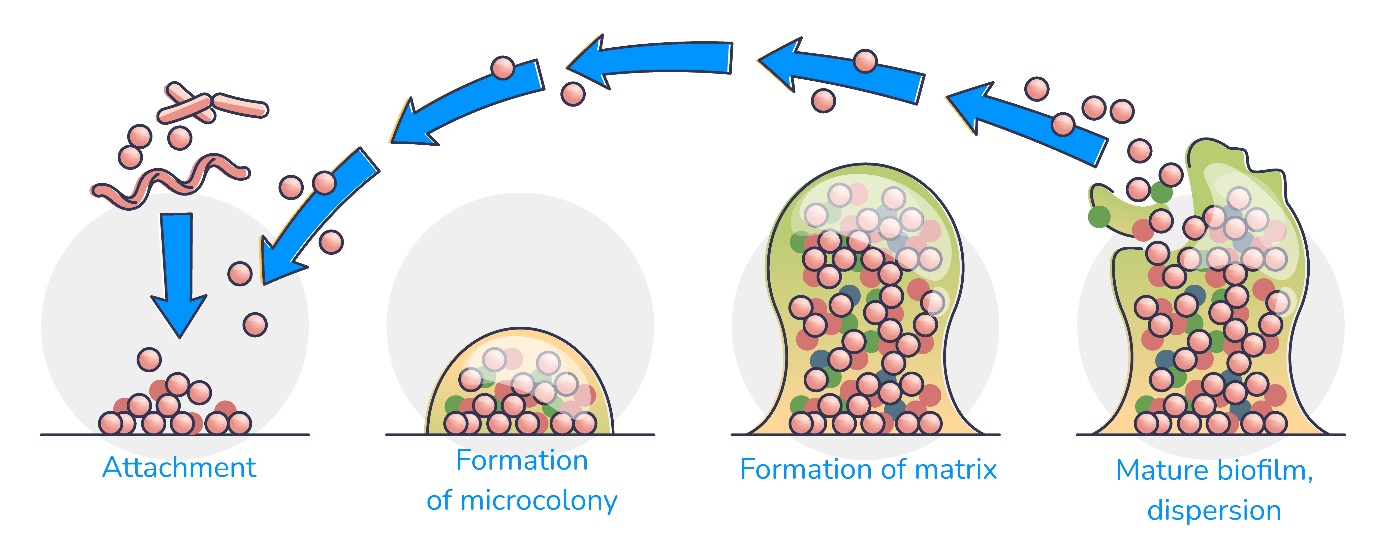

This occurs in four stages:

- Attachment: Bacterial cells attach to an abiotic surface

- Colony formation: Microcolonies are formed, given the right growing conditions for them to thrive

- Growth: The microcolony continues to grow into a matrix, which constitutes the biofilm

- Dispersal: Macrocolonies are formed, leading to mature biofilm stage and the dispersion of cells, which in turn can further colonize the irrigation system

That biofilm is a fertile breeding ground for pathogens[2] and can lead to blockages in the irrigation system, so you’ll want to prevent biofilm from forming in the first place, or remove it if it’s already present. Not doing so is often very costly in terms of lost production, as well as in treatments for plant disease which fail to resolve the root cause of the problem.

That biofilm is a fertile breeding ground for pathogens[2] and can lead to blockages in the irrigation system, so you’ll want to prevent biofilm from forming in the first place, or remove it if it’s already present. Not doing so is often very costly in terms of lost production, as well as in treatments for plant disease which fail to resolve the root cause of the problem.

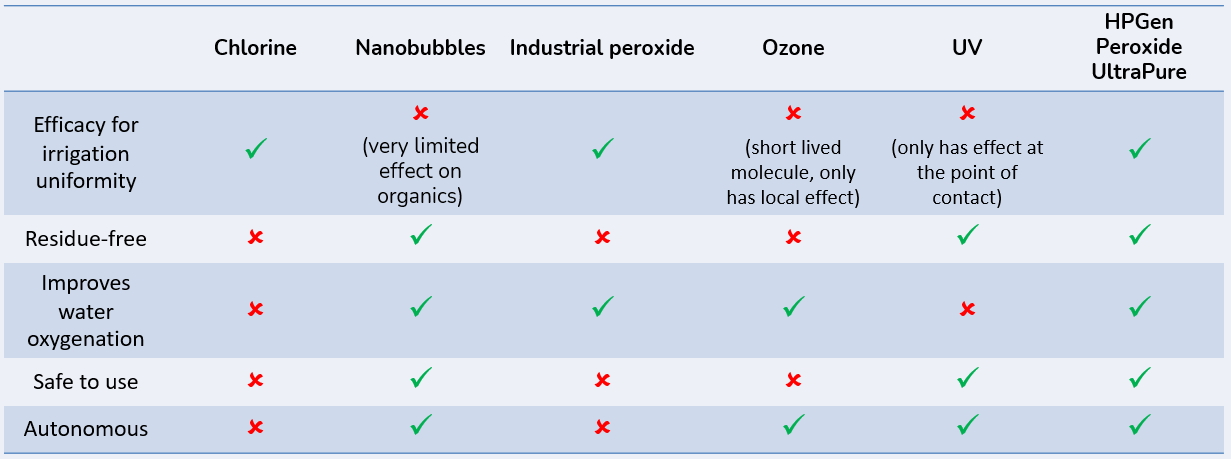

But how can biofilm be addressed? The table below compares some solutions for preventing and removing biofilm.

Solutions such as ozone or UV are not effective with biofilm, as they only have a local effect which does not extend along the irrigation lines. Nanobubbles in turn have a very limited impact on the organics that form the biofilm, and struggle to achieve the required level of biofilm control:

An effective way to prevent the buildup of biofilm is by using oxidizers such as chlorine or hydrogen peroxide. Chlorine, while effective against biofilm, is not a good solution as it could also damage drippers. In addition, chlorine leaves behind disinfection byproducts after use which remain in the water or soil, negatively affecting the plants.

Studies on hydrogen peroxide have shown its effectiveness in combating biofilm and preventing clogging of the irrigation system[3], while having the added benefit of oxygenating the water. Once dosed into the irrigation system, hydrogen peroxide will dissolve very well in water. As soon as it contacts any organics it will oxidize them. This will slowly erode biofilm, and importantly it will prevent the formation of more biofilm. It is very common to see a gradient in concentration from the injection point down to the end of the irrigation lines, with the gradient being more steep the more organics a system has. After use, peroxide molecules will become water and oxygen. However, industrial peroxide contains more than just peroxide, and accordingly it has a few major drawbacks. At high concentrations, hydrogen peroxide is a hazardous substance and requires strict safety measures. It also comes with high levels of impurities, especially additives consisting of heavy metals and chelating agents used to minimize losses of hydrogen peroxide during transport and storage. These additives have a detrimental effect in the water and crop as they accumulate over time. Notably, these impurities are known to accumulate in the substrate and root zone of the plants, where they create a local area with high salinity. Not only does this impact osmotic pressure in the water in the vicinity of the root zone, which hampers fertilizer uptake, but it also blocks the water paths to the root zone. This means that despite using hydrogen peroxide, biofilm and pathogens still occur and adding more peroxide only exacerbates the problem at plant level. Finally, users depend on an often volatile supply chain with uncertain availability and pricing.

Peroxide UltraPure™: an effective weapon against biofilm

Peroxide UltraPure™ produced by the HPGen system, circumvents these drawbacks by producing an ultra-pure form of hydrogen peroxide, Peroxide UltraPure™, directly on-site. Produced at safe, low concentrations, directly at the point of use, no stabilizers are required. This makes it ideal for agricultural use, where purity is vital to achieve the full potential of hydrogen peroxide: having no stabilizers means peroxide has optimal reactivity, so it will be able to reach the full depth of the irrigation system, including substrate and plant root zone. These are kept free of biofilm, promoting a healthy uptake of water and nutrients that improve health and vigor of the plants. The HPGen system also operates autonomously: hook up the system to your irrigation system, switch it on and it will take care of the rest.

The effectiveness of Peroxide UltraPure™ against biofilm

The safe concentrations of Peroxide UltraPure™ produced by HPGen may have you wondering: How effective is it against biofilm?

We’ve installed numerous HPGen systems generating Peroxide UltraPure™ on-site, used in a variety of crops, in different parts of the world, where irrigation water quality also varies greatly. Peroxide UltraPure™ has been shown time and again to be effective in combating biofilm, as evidenced by the examples below.

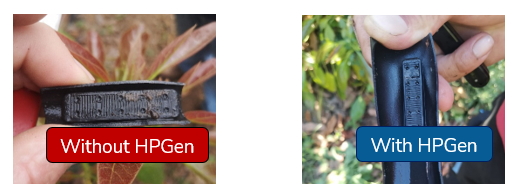

Israel, irrigation water from wastewater plant. Emitters from untreated irrigation lines (left, control group). The brown matter on the emitter diaphragm is accumulated bio-foul. In sharp contrast, emitters from HPGen-treated irrigation lines (right) are nearly as clean as new after over 6 months of exposure to unfiltered secondary treated waste water from an open reservoir.

Portugal avocado plantation, with irrigation water from dam. Drippers from untreated irrigation lines (left, control group). The brown matter on the channels is accumulated bio-foul. Emitters from HPGen-treated irrigation lines (right) are nearly as clean as new after two months of dosing Peroxide UltraPure.

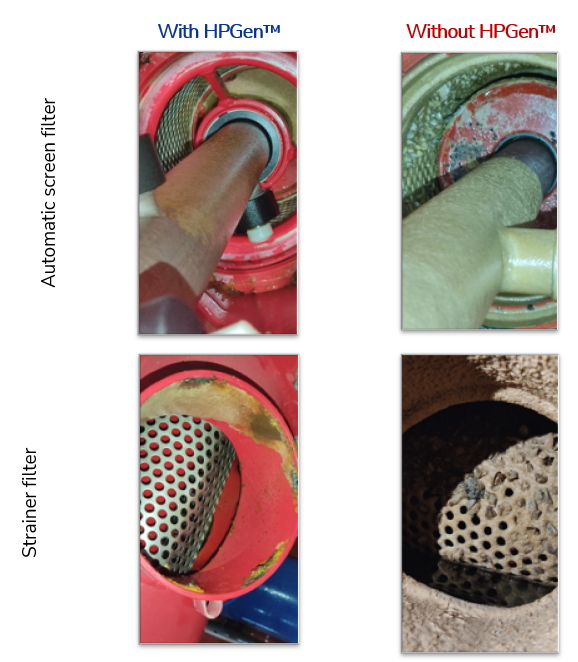

Spain irrigation community, with irrigation water from an open canal with heavy organic load. Filters and strainers in the section treated with HPGen Peroxide UltraPure look clean, while those without HPGen show significant growth of biofilm and even zebra mussels.

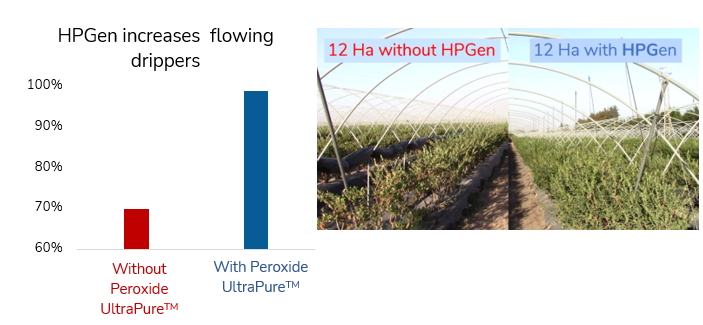

In field studies, Peroxide UltraPure™ has been shown to achieve very uniform irrigation in drip systems. In a controlled test on a 12 hectare organic blueberry plantation, about 30% of the drippers were found to flow below accepted values. Within a few weeks of starting injection of Peroxide UltraPure™, nearly all drippers were back to flowing water. This had a very positive effect on the crop, which grew with more vigorously and healthily.

Blueberry plantation comparing side by side the effect of Peroxide UltraPure.

Based on very comprehensive studies and experience across the globe, we are able to recommend optimal dosing regimens, which are also backed by academic studies (e.g. Effectiveness of hydrogen peroxide treatments in preventing biofilm clogging in drip irrigation system[4]). This includes continuous dosing with recommended concentrations based on multiple parameters including water quality, irrigation system, irrigation regime, crop, climate and others. HPNow has numerous case studies and will be happy to advise the best approach for your particular situation.

For more examples of how HPGen has helped improve irrigation for growers around the world, please take a look at some of our case studies. Our team is happy to answer any additional questions you may have about this, so please feel free to get in touch.

About HPNow

HPNow addresses growing global challenges in clean water and sanitation through its range of on-site, autonomous, safe and sustainable hydrogen peroxide generation solutions. Headquartered in Copenhagen, and with representation across Europe, the Americas and Asia, they address their clients’ water treatment needs in market segments ranging from agriculture and aquaculture, to industrial and drinking water treatment. HPNow is a technology and market leader in on-site generation of hydrogen peroxide, and is continuously striving to further advance its technology and products in order to meet growing market needs and rising global demand.

Stay in the loop by following HPNow on LinkedIn, Facebook, Twitter and Instagram.

More news