Sustainable production model with AI in VF

Added on 31 January 2023

At Çukurova University (ÇÜ) Faculty of Agriculture, the data obtained from lettuce production with indoor vertical farming method are combined with artificial intelligence to create a suitable production model.

With the study, in which 95-98 per cent water saving is achieved, it is aimed to determine the appropriate climatic conditions in lettuce cultivation and to obtain high yields in the shortest time.

A study is being carried out within the scope of the project "Optimisation of Model Plant Lettuce Production Techniques with Artificial Intelligence by Indoor Vertical Hydroponic Farming Method", which was implemented by the General Directorate of Agricultural Research and Policies of the Ministry of Agriculture and Forestry (TAGEM), Çukurova University (ÇÜ) and a company in September last year.

A 10-person project team grows lettuce with soilless agriculture on tiered shelves in Çukurova University Indoor Vertical R&D Facility. In the facility, the data obtained by studying LED lighting combinations, the development of the plant depending on the length of the days (photoperiod), different temperature and humidity rates are combined with artificial intelligence.

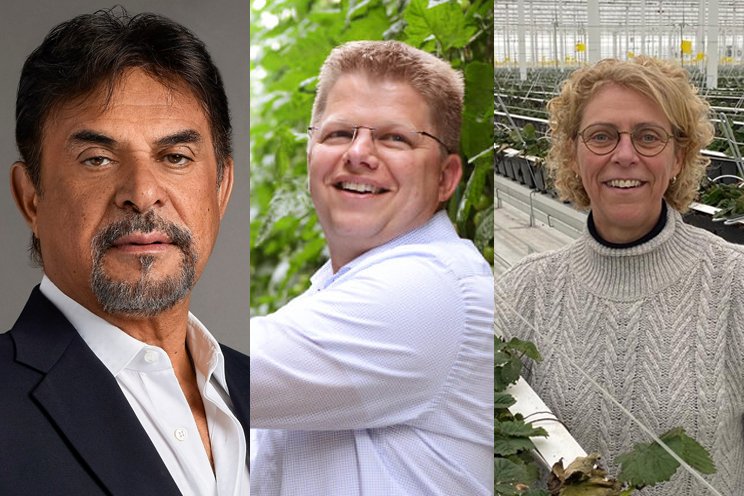

With the study, in which 95-98 per cent water saving is achieved, production models are created in different combinations in the light of the data. Prof. Dr. Hayriye Yıldız Daşgan, a faculty member of Çukurova University Faculty of Agriculture, Department of Horticulture, told AA correspondent that with the project, they can provide cultivation with completely controlled environmental conditions in plant factories or indoor vertical farming facilities.

Explaining that with the study, they illuminated with LED lamps instead of sunlight, adjusted the day and night temperatures at the level desired by the plant with heating and cooling systems, Daşgan stated that they also ensured the control of environmental conditions such as humidity and carbon dioxide ratio.

"We cultivate in water without using soil"

Stating that the water used in agriculture is becoming a scarcer resource day by day due to climate change, factors such as temperature and flooding will negatively affect plant cultivation, Daşgan continued as follows: "Indoor vertical farming facilities offer the possibility of fully controlled plant cultivation independent of climate and space in marginal areas where soil farming cannot be done, even in city centers, inside buildings and on roofs. We cultivate in water without using soil. Aquaculture is a technique used where soil is not available and/or in conditions where soil is not suitable for cultivation. Although it is cultivated with water, it is a cultivation technique that uses water very economically. We use only 2 to 5 percent of the water used in the soil. We can grow plants by saving 95-98 percent of water. This will be a very good solution to the threat of drought. Indoor vertical farming facilities with soilless production will be a very good solution to sustainable food security threats such as climate change, drought and epidemics."

Daşgan said that with the indoor vertical farming method, plants grow in a shorter time compared to soil and greenhouse cultivation. Pointing out that with this system, uninterrupted, continuous production can be made throughout the year since it is not dependent on climate and natural conditions, Daşgan said, "These are very high-storey systems with very high productivity per unit area. While you can grow 8-10 lettuce on a square metre area in the soil, you need to multiply according to the number of floors in layered systems. This type of agriculture is quite new not only for our country but also for the world. Since the climatic conditions in our country are not very disadvantageous, soilless production still continues in greenhouses. Thinking that we may need it in the coming years, we have already started R&D studies."

Daşgan said that they are currently growing lettuce within the scope of the project, and that they will work on green leafy vegetables such as spinach, cabbage, parsley and dill in the following processes, and then on strawberries, tomatoes, peppers and aubergines.

"It will be ensured to create the most suitable climatic conditions"

Horticulture Department Faculty Member Assoc. Prof. Dr. Bekir Bülent Arpacı stated that approximately 28 thousand data to be obtained from the studies will be processed and different combinations will be created.

Emphasizing that they aim to create an environment where the product can be grown at the most favorable level by associating climate data with the morphological and physiological characteristics of lettuce, Arpacı said, " The data obtained in this way will be associated with artificial intelligence and those who establish this system in later studies will be able to create the most suitable climatic conditions for lettuce cultivation."

Source: Growtech via Anadolu Ajansı

Photo Credit: Eren Bozkurt, Anadolu Ajansi

More news