Cutting-edge nanobubble tech sustainably increases violet production

Added on 25 January 2023

Each crop of flowers and ornamental plants at Harster needs very specific conditions, therefore each section of the greenhouse has a different climate.

Improving root development sustainably

Crop health and quality starts at the roots. Healthy root development leads to better crop quality, increased production and more resilient plants. Harster’s Head Grower, Bart Kouwenberg, sought sustainable solutions to improve root development for more resilient plants.

Prior to installing Moleaer’s nanobubble generator, the growth cycle was on average 7-8 weeks from Plugs and was generally inconsistent.

It typically takes 4-5 days to ship plants to distributors from Harster’s greenhouses, which can be hard on plants. They often arrive with early signs of wilt, something that can hurt the bottom line and upset customers.

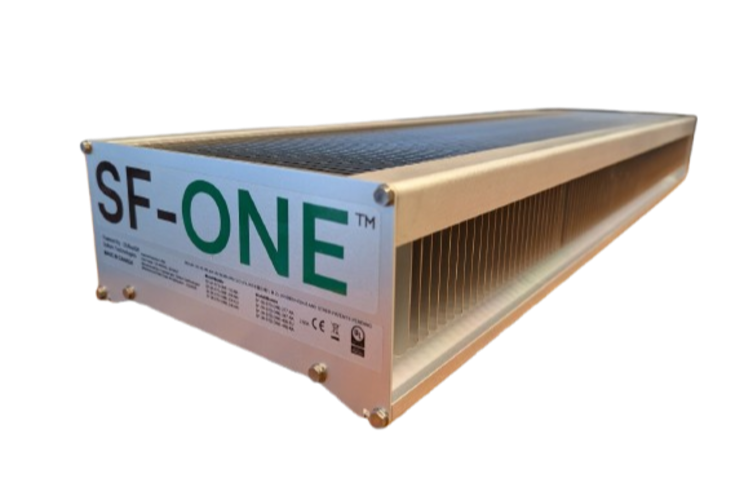

The nanobubble solution

Moleaer’s nanobubble generators provide a chemical-free, cost-efficient, sustainable solution to improve water quality by increasing dissolved oxygen (DO) levels in irrigation water supplies. The increased dissolved oxygen levels support root development and oxygenation, increasing nutrient uptake efficiency. It also has been proven to reduce pathogens like Pythium and Phytophthora by as much as 90% and remove and prevent biofilms from surfaces.

Results

Since installing Moleaer’s nanobubble generator, the team at Harster has reduced the crop growth cycle on its violets, achieving a consistent 6 week grow cycle, enabling increased production and profitability. Bart Kouwenberg, Head Grower at Harster Greenhouses, said: “Using a Moleaer nanobubble generator led to bigger plants and more root mass. Propagation was also sped up by 10 days and reduced the final weeks of flowering by 10 days.”

Through nanobubble technology, Harster increased the DO concentrations in their irrigation water up to 21 ppm, even when water temperature increased.

They were also able to reduce their fertilizer usage in their entire greenhouse from an EC (electrical conductivity, or the measurement of salts dissolved in water) of 1.7 to 1.4 ppm. This was an 18% reduction in fertilizer and is due to better root development and improved nutrient uptake efficiency by the plants.

Lastly, Harster’s customers also noticed the benefits of nanobubble technology. From producing healthier root systems and more resilient plants irrigated by nanobubble-enriched irrigation water, they found that even after 4-5 days of transport to their distributors, the plants arrived stronger and healthier.

More news