SmartWash solutions keeps consumers safe from microbes

Added on 21 March 2023

Foodborne illness caused by microbial contamination from pathogens such as Salmonella and E. coli on fresh produce is a serious health concern. Recent public health crisis includes more than 250 people who became ill from E. coli contaminated salad in the United Kingdom. While a salad mix containing Salmonella contaminated arugula was withdrawn from markets and restaurants in Poland.

Initial contamination can come from many sources, including manure, soil, wildlife, irrigation water and human handling. This contamination is difficult to eliminate, and can cross-contaminate additional produce during the production and packaging process. However, that contamination can be mitigated via disinfection in an effective, innovative produce wash process.

For decades, chlorine, derived from sodium hypochlorite (NaOCl), has been the preferred option for sanitizing produce wash lines and protecting consumers from foodborne pathogens. Chlorine’s efficacy is dependent on several factors, including wash water temperature, pH levels, and the concentration of free chlorine and organic materials in the water. However, poorly controlled chlorine application can lead to the production of chlorate residue on produce.

Chlorates are a disinfection-by-product (DBP) of chlorine-based products and have been found by the European Union (EU) to be a health concern for at-risk groups such as children and people with existing thyroid problems. While the International Programme on Chemical Safety (IPCS) stresses the health risks of exposure to chlorates and chlorine by-products are minimal in comparison with the risks associated with inadequate disinfection, the EU has instituted policies to limit chlorate exposure to a very stringent Maximum Residue Level (MRL) of 0,7 mg/kg for leaf vegetables.

In the VEG-i-TEC study, which was conducted on a commercial wash line in normal operation, after a full 8-hour production run of Iceberg Lettuce and Lollo Rosso, chlorate levels increased by 0,03 and 0,23 respectively, well below the MRL level of chlorates.

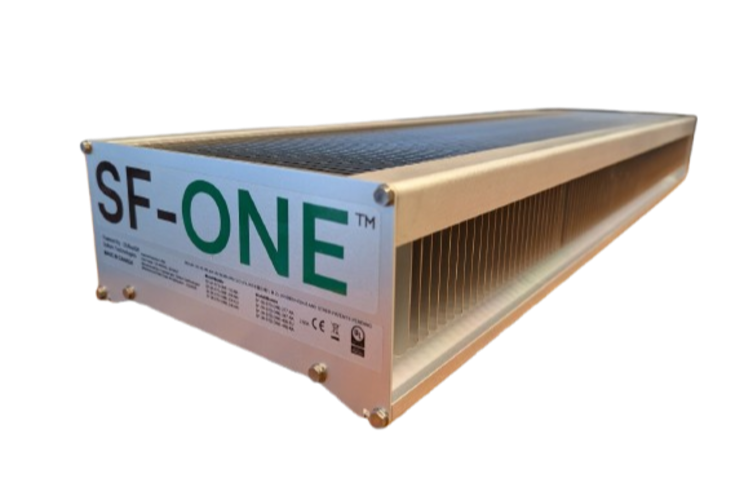

Most companies manage produce wash system chemistry as a manual process, often dosing an excess of NaOCl to ensure minimal levels of chlorine are maintained. SmartWash Solutions, an independent business unit of Taylor Farms, the USA’s largest fresh cut processor, developed a process control system to continuously monitor, automate and maintain precise pH and low chlorine levels in produce wash lines, greatly reducing the amount of NaOCl required. The system has seen wide adoption in the USA, Australia, Canada and Mexico and is now available in the EU.

Higher doses of NaOCl result in higher concentrations of chlorates. The SmartWash Solutions system minimizes NaOCl use and chlorate formation by a combination of sensors, cloud-based reporting, the introduction of SmartWash Original processing aid, and automatic dosing of NaOCl.

“EU Governments want to ensure people have access to safe, healthy vegetables,” said Ewoud Buter, General Manager, SmartWash Solutions BV. “This research confirmed that the precise controls of the SmartWash Solutions system was able to achieve adequate disinfection to control pathogens while minimizing residual chlorate levels to far below the MRL. There is simply no reason for EU produce processors not to use chlorine to disinfect their product and keep consumers safe

European produce processors who want to join SmartWash’s large worldwide customer network in improving the safety, efficiency and control of their produce wash lines today can get more information by contacting +31.6.1544.1290.

More news