Under the bright lights with Fohse

Added on 16 October 2023

In truth, it wasn’t until 2018 or so that LED technology finally turned the corner and became the obvious choice for commercial growers across the United States. Even today, there are HPS holdouts—mostly on the West Coast—who aren’t completely convinced of LEDs’ performance, environmental, and long-term cost benefits, but the data doesn’t lie. LED lights have proved to produce more light than HPS on a per-watt basis while creating less heat, and they also degrade at a slower rate and boast a much longer lifetime.

LED technology also allows cultivators to manipulate light spectrums at various stages of plant growth to influence cannabinoid and terpene production. In an industry becoming more fixated on crop-steering and relying on analytics to determine which strains to grow, LED technology has become a critical component of the equation.

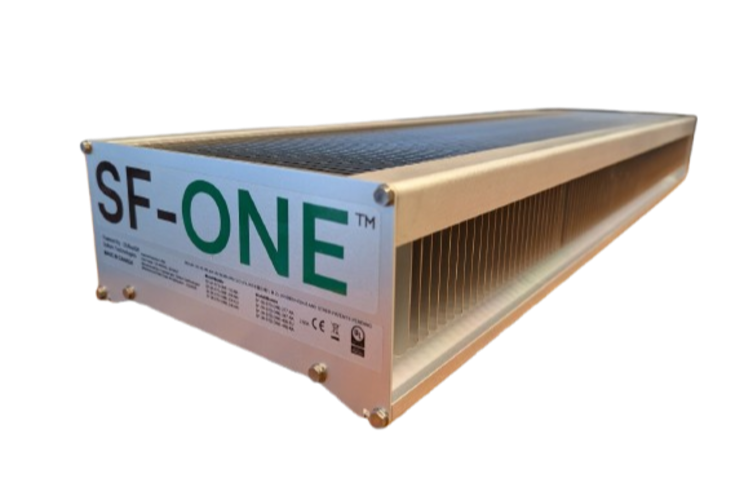

As a leading LED manufacturer, Fohse has sold many tens of thousands of lights to growers around the world. The company’s lamps can be found in more than 700 indoor and greenhouse facilities across the U.S. and about twenty other countries. Founded in Las Vegas in 2015, Fohse recently was named among the twenty fastest-growing private companies in the U.S. by Inc. magazine. The Las Vegas Sun reported the company generated revenue of about $70 million in 2022, and Chief Executive Officer Brett Stevens said the figure soon could approach $200 million.

As chief technical officer, Alex Gerard leads the company’s engineering department, keeps abreast of new technologies, consults with growers, and works on new designs to keep the company’s customer base growing. Chief Horticulture Officer Mike Howard “dabbles in a little of everything” from sales and marketing to consulting with growers and facilities across the U.S. As a former commercial cultivator in Nevada, he was an early LED adopter and is intimately familiar with the issues growers confront on a daily basis.

Technology has played a major role in the success of commercial cultivation over the past five years. What matters most when cultivators evaluate lights?

Gerard: A lot of people who tried first-generation LEDs had pretty bad experiences. In the past, people said you couldn’t get the same yield with LEDs, and there was a lot of misinformation about quality as well. When companies like ours started coming along and doing research and development (R&D) the right way, we had to overcome this initial bad feedback.

It’s all based on a light’s ability to put down more energy more efficiently, which then produces more action within the plant. Good lights actually can increase yields quite significantly—20-, 30-, even 40-percent increases in yields are not unusual at all.

Photo: Alex Gerard on the left and Mike Howard on the right. All Photo Courtesy of Fohse.

More news