Ultrapure peroxide leads to lower plant mortality and increased disease control

Added on 26 January 2023

Hydrogen peroxide (H2O2) is a highly versatile and sustainable molecule. It is widely used in agriculture to treat irrigation water and protect crops. As the H2O2 molecule is essentially water with an extra oxygen atom, there are no dangerous byproducts following use, making it particularly suitable for edible (including organic) crops. As an added bonus, the oxygen in hydrogen peroxide is released upon use, increasing dissolved oxygen levels in irrigation water and soil.

Industrial peroxide vs Peroxide UltraPure™

There are however some drawbacks in utilizing industrial-process based hydrogen peroxide in agriculture. In the traditional supply chain, industrial hydrogen peroxide is produced in large manufacturing plants, at high concentrations, requiring stabilizers that minimize losses of hydrogen peroxide during transport and storage. In contrast, Peroxide UltraPure™ is generated directly on-site through a patented electrochemical process that yields the highest purity available in the market, >99.999 %.

Growers report lower disease pressure and plant mortality

In order to demonstrate the positive effects of Peroxide UltraPure™ versus industrial peroxide, a comparative study was carried out by growers representing different crops, irrigation systems and greenhouses. These included a strawberry propagator, a macadamia trees nursery (both using micro-sprinklers and foggers), a lettuce grower with drip irrigation and water recirculation, as well as a hydroponics cucumber grower with drip irrigation. In all these cases growers had extensive experience with industrial peroxide, and switched either their whole or part of their facility to Peroxide UltraPure™. Dosing regimes and concentrations were kept at the same levels to provide a fair comparison.

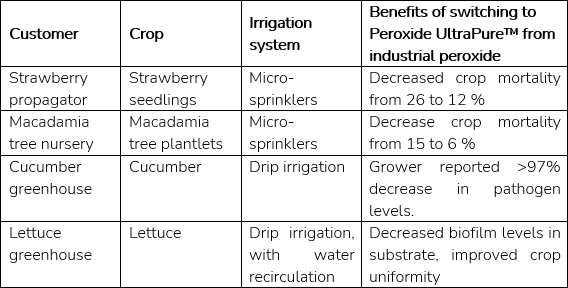

The results from these controlled tests are summarized in Table 1.

Table 1: Growers of different crops have reported positive effects of switching from industrial peroxide to Peroxide UltraPure™

In particular, as shown in Table 1, mortality rates for a strawberry propagator were at 26% using industrial peroxide through the micro-sprinkler irrigation system. Over time, stabilizer accumulation on the sprinklers had resulted in blind spots in the irrigation system where biofilm could grow, and in turn block emitters – which meant plants were not being irrigated properly. At the same time, some plants had outbreaks of botrytis which industrial peroxide was not able to control. After switching to UltraPure™, mortality rates decreased from 26 to 12 %. Irrigation became more uniform, with Peroxide UltraPure™ dislodging a good amount of biofilm thanks to its stronger oxidizing potential, and botrytis outbreaks were virtually eliminated from the facility. Dissolved oxygen content in irrigation water also increased by 3 ppm, as peroxide was activated easier without stabilizer. These meant a more robust root system and improved plant health, which translated to the decreased mortality observed.

Similar results were observed at a macadamia plantlet nursery with overhead irrigation, with mortalities decreasing from 15 to 6 % after replacing industrial peroxide by Peroxide UltraPure™.

In a cucumber greenhouse, irrigation water was sourced from a river with presence of pythium. Industrial peroxide had been used for many years, but there was still a high incidence of pythium at the facility. Analysis of the water showed a high presence of pythium zoospores, with levels of 375 zoospores/mL despite dosing upwards of 30 ppm of industrial peroxide. Pythium was causing pathology issues at the plants, and a poor crop uniformity. Upon additional inspection, it became clear that industrial peroxide was not able to reach throughout the whole irrigation system, as there were pockets of biofilm where pathogens remained out of reach. This is due to the effect of the stabilizer, which accumulated in zones of the irrigation system facilitating growth of biofilm and blind spots. Switching to Peroxide UltraPure™ prevented the accumulation of stabilizers, and Peroxide UltraPure™’s stronger oxidizing power enabled full removal of biofilms from the irrigation system. Pythium analyses were consistently lower than before, with levels below 10 zoospores/mL. This resulted in a healthier, more uniform crop with a more predictable performance.

In a lettuce greenhouse with a strong emphasis on water conservation, industrial peroxide was also part of the water treatment program. In this greenhouse irrigation water is recycled, which, unless water is properly treated, can facilitate the spread of pathogens as any infected plant can quickly infect the rest of the crop through water-borne transmission. Industrial peroxide was being dosed in the irrigation system, but the high level of impurities accumulated in the recirculation water, on the one hand increasing salinity levels at the substrate, and on the other limiting the oxidizing power of peroxide, resulted in abundant biofilm present in the substrate and irrigation system. Switching to Peroxide UltraPure™ meant that impurities no longer accumulated in the water and substrate. This reduced salinity and enabled the lettuce to better absorb fertilizer thanks to the lower osmotic pressure. At the same time, Peroxide UltraPure™’s superior reactivity kept biofilm under control. This was not only beneficial for plant health and rate of their growth, but it also meant less slugs were found in the facility as they are attracted by biofilm.

Negative effect of stabilizers

The difference between Peroxide UltraPure™ and industrial peroxide can be attributed to the presence of stabilizers in the latter. The industrial process utilizes traditional chemical catalysts, such as palladium, and abundant solvents such as trioctylphosphine or trimethylbenzene, traces of which find their way to the output solution. Additionally, in order to minimize decomposition of the volatile H2O2 molecules at high concentration, stabilizers need to be added. Stabilizers minimize interaction of the impurities accumulated during the industrial production process with hydrogen peroxide. Stabilizers contain heavy metals such as silver, salts and chelating agents.

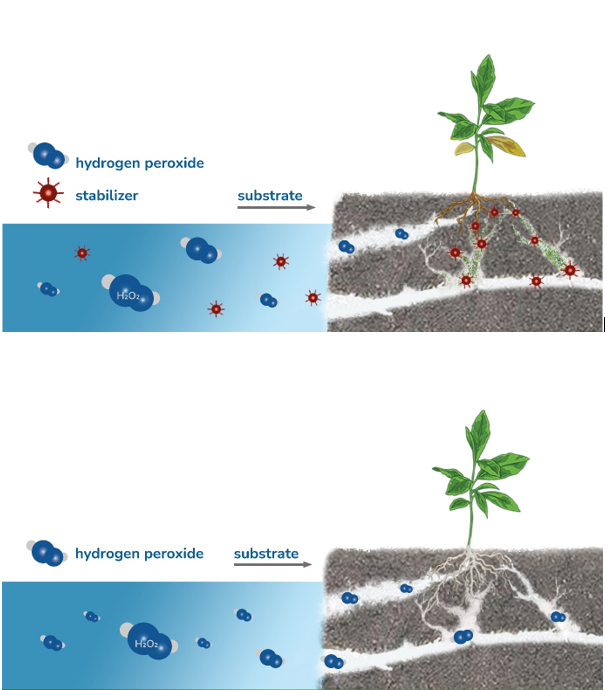

Unfortunately, these metal catalysts and stabilizing agents also have several negative effects. They can accumulate in the substrate, blocking water pathways and preventing water (and fertilizers) from reaching part of the root zone (Figure 2). Accumulation of stabilizers in the water or substrate also increases local salinity in the root zone, which hinders uptake of fertilizers by the plant due to increased osmotic pressure. Finally, stabilizers also reduce the effective oxidizing strength of hydrogen peroxide, which makes it less effective against biofilm and plant pathogens such as pythium, phytophthora and fusarium.

As a result, even if peroxide is found in the water, it will encounter blocked pathways en route to the root zone where it is most needed towards crop protection. The pathway blockage further leads to reduced access of the root zone to basic nutrients, and in turn slower plant growth, and increased susceptibility to disease.

Figure 3: Above: hydrogen peroxide with stabilizers can block water pathways in the substrate, leading to biofilm buildup and yellowing leaves. Below: H2O2 can move freely into the substrate, unhindered by stabilizers, to work its beneficial effects on the plant’s root system.

Another issue of concern is toxicity of stabilizers, particularly as they contain heavy metals. These metal-based stabilizers will remain after hydrogen peroxide has been used, and will accumulate over time in the substrate or recirculated water, and eventually find its way to the plants. Heavy metals such as silver are toxic to the soil microorganisms and plants, and has a negative effect on plant nutrient uptake and genetic expressions – an effect that has been highlighted in various studies.

Peroxide UltraPure™

Peroxide UltraPure™ is intrinsically stable; without requiring any addition of stabilizers, it is stable for up to 6 weeks in an agriculture facility. Peroxide UltraPure™ is accordingly very safe for agriculture use, as there are zero residues that can have detrimental effects on crops, no risk of overdosing to hazardous levels, and no buildup of stabilizers with continued use or recirculation. Additionally, the use of Peroxide UltraPure™ eliminates the occupational hazards involved in dealing with high-concentration bulk peroxide. Finally, Peroxide UltraPure™ is highly sustainable – it is made directly on site from only water and electricity, without any chemicals inputs; does not require transportation from remote production facilities, and can reduce carbon emissions by up to 50% when using standard EU grid, and up to 100% when coupled to renewable sources.

Peroxide UltraPure™ benefits observed in the field

Growers observed visible differences after switching to Peroxide UltraPure™.

- Improved oxidizing ability: Growers reported a stronger effect on plant diseases such as pythium (Figure 2). We attribute this to Peroxide UltraPure™ not containing any stabilizers that may limit its oxidizing strength.

- Lowered mortality rates: Growers consistently reported lower crop mortalities when using Peroxide UltraPure™. Maintaining the substrate and root zone free of stabilizer accumulation enables improved distribution of water and fertilizer throughout the whole root zone and prevents buildup of osmotic pressure. This leads to improved plant health and vigor, and results in lower mortalities (Figure 2, 3).

- Improved crop uniformity: Keeping water free of foreign salts and the superior efficacy of Peroxide UltraPure™ against blockages in the emitters helped growers achieve a more uniform and predictable crop.

In addition to the agronomical benefits reported above, Peroxide UltraPure™ also improves farm safety – it is generated without any chemical inputs at safe concentration levels. The Peroxide UltraPure™. on-site generation process is completely autonomous, and eliminates dependance on external hazardous supplies that require dedicated storage and handling.

Overall, the improved plant health and lower mortality rates achieved with Peroxide UltraPure™ represent a strong positive financial impact for agricultural facilities, while at the same time improving predictability, stability, safety and sustainability of the operations.

About HPNow

HPNow addresses growing global challenges in clean water and sanitation through its range of on-site, autonomous, safe and sustainable hydrogen peroxide generation solutions. Headquartered in Copenhagen, and with representation across Europe, the Americas and Asia, they address their clients’ water treatment needs in market segments ranging from agriculture and aquaculture, to industrial and drinking water treatment. HPNow is a technology and market leader in on-site generation of hydrogen peroxide, and is continuously striving to further advance its technology and products in order to meet growing market needs and rising global demand.

Stay in the loop by following HPNow on LinkedIn, Facebook, Twitter and Instagram.

More news