Is vertical farming profitable?

Added on 08 November 2023

This article in brief:

- Automated vertical farming is profitable when agronomy and technology are 100% accurate.

- A flexible system will keep you resilient in the rapidly changing supply and demand market.

- As a rule of thumb, an automated vertical farm is profitable from three climate cells onwards.

Is automated vertical farming profitable?

"Yes, provided you do it right. I often compare automated vertical farming to a "Symphony of efficiency." All the elements come together in a symphony, making it a beautiful piece of music. This is exactly how it works with automated vertical farming. Your business case is profitable when the technology, agronomy, and product pricing are all in perfect sync.”

%20kopie.png?width=800&height=601&name=Artechno%20Factory%20Feb%2023%20(14)%20kopie.png)

What makes that symphony successful?

"You have to make sure the crop gets everything it needs, no more and no less. Think of water, oxygen, nutrients, temperature, humidity, airflow, and the required CO2 level.

Put agronomy and technology to work in a vertical farm to give the crop those optimal conditions. First, agronomy determines what the plant needs to grow optimally.

Then, the system must be designed to allow you to rule those conditions with 100% accuracy. This is what will determine the success or failure of your business model.

What goes wrong when a business case fails?

"If the symphony is not perfect, your business case goes south. There are several reasons why the tide could turn. It always starts with the right choices and configuration of the cultivation system. Next, the operational cost of the system is the success maker or deal breaker.

Labor should be wisely automated in the configuration, and your energy contract should be at the right volume and price.

Agronomy should produce the required kilograms, and then when everything comes together in the proper proportion and timeline, you will experience that symphony and, thus, a positive business case.

Companies fail because they have chosen a system without the symphony's presence. If not "every dot is connected" within the chain of CEA, nine times out of ten, it's in the operational costs (Opex). The capital expenditures (Capex) on a system with a life cycle of 15-20 years are not a determining factor. On the other hand, despite automation and AI, a good operator is still fundamental. Attention and responsibility to your business are always vital in any business.

Which flaws make a business case unprofitable?

"For example, your crop recipe may not be up to par, so the quality of your crops will not be optimal.

To be profitable, crops must grow optimally at the right growth rate. Delay results in higher cost price per kg.

Another possibility is that too much labor is required, which incurs excessive costs and increases the risk of contamination.

As a rule, labor is expensive in Western countries, and automation benefits the profitability of the vertical farm. Automation is an essential part of the symphony.

In other words, if you have made the right choices in system and organization, a vertical farm is a prosperous business venture. The relatively new vertical farming industry has seen quite a few gold diggers over the past 10 years. However, Gartner's chart clearly shows the stage we are at as a business. The shake-out (trough of disillusionment) occurred over the past 12 months, and now is the time for the professionals to step in.

The industry was viewed with suspicion and disbelief as a consequence of the golddiggers, which is understandable and even still justified for several projects. Due to the fact that some companies aren’t successful in making a vertical farm run successfully, vertical farming has acquired the reputation of being expensive and unprofitable. It is an entirely unjustified reputation, but you have to know the ins and outs to properly validate it, which is valid for any business.

The vertical farming industry has a rapidly changing supply and demand market; how can it stay resilient?

"That has everything to do with the flexibility of the system you invest in.

The market is indeed fluctuating, and you see that supply and demand, both from consumers and the market, may change rapidly. You have to build a flexible system to go with the flow and can quickly switch to other varieties or crops.

Suppose you have a system that allows you to grow only spinach. Then you've put yourself in a vulnerable position. But if you have a system that allows you to grow multiple crops, you will be able to serve the ever-changing market demands.”

%20kopie.jpg?width=800&height=600&name=Junior%20crops%2001-08-22%20(4)%20kopie.jpg)

What exactly does flexibility in vertical farming entail?

"There are two sides to that. First, technical:

- Multiple climate cells = more climate zones and thus the possibility of multiple crops

- Harvesting and packaging different crops in the same logistics area

- Bandwidth of climate control and operation

- Combining several varieties within the same environmental recipe

- Multiple crops in one VF configuration are possible

More cells means more flexibility.

In addition, agronomy allows you to adapt your crops to the needs of the market in terms of:

- Structure

- Taste

- Growth rate

- Color

- Nutritional value

- Preservability (shelf-life).

If symphony is not achieved, it can be adjusted within certain limits.

How does Artechno Growsystems factor in the required flexibility?

"We can easily adjust climate, light, and irrigation recipes. Any new insights and knowledge gained at our Cultivation & Research Center in De Lier, the Netherlands, are applied at our customers’ factories. Our system's compartmentalization (various climate zones) benefits the flexibility of the daily operation in terms of multiple crops and cleaning and hygiene of the system.

There is, of course, a limit to flexibility. Because of the height difference, we can't suddenly grow high-wire crops in a climate cell designed for leafy greens. But within a group of crops that fit within the same dimensions, our system allows the flexibility to make adjustments so you can quickly respond to changed market demands.”

Will Growing multiple crops in a vertical farm make a big difference to the business case?

"Absolutely. It gives you a strong position in the market. You can serve various target groups, including supply retailers with a large assortment.

That is how we set up our systems at Artechno Growsystems. We work with different compartments in which the crops are grown. Within one AVF+ Factory, a broad spectrum of different crops can be produced.”

The vertical farming market is erratic; do opportunities arise because of this?

"Yes, because an automated vertical farm can grow many crops. From short-cycle crops to strawberries, microgreens, herbs, and young plants. Or opt to grow young plants for decorative purposes, but also cocoa and other exotic crops.

This system offers many possibilities and will significantly impact the horticultural sector. We are on the eve of the revolution of growing crops in a new way.”

Is it necessary to procure a giant vertical farm to be profitable?

"No. Every business case is different, but you will generally run a profitable business from three climate cells onwards.

From what size your AVF+ Factory becomes profitable depends on several variables, including the type of crop, the country in which the automated vertical farm is located, the price of the product, and the energy costs. That said, you can develop a sound business case almost anywhere in the world.

Then you can scale up by simply adding compartments, resulting in:

- Maximum ROI

- Anticipate market demands

- Scaling with business growth.”

What does the customer journey entail if a customer is interested in automated vertical farming?

"We only embark on a sales journey with a customer when we are sure the business case is profitable. That's why we follow the customer journey roadmap below.''

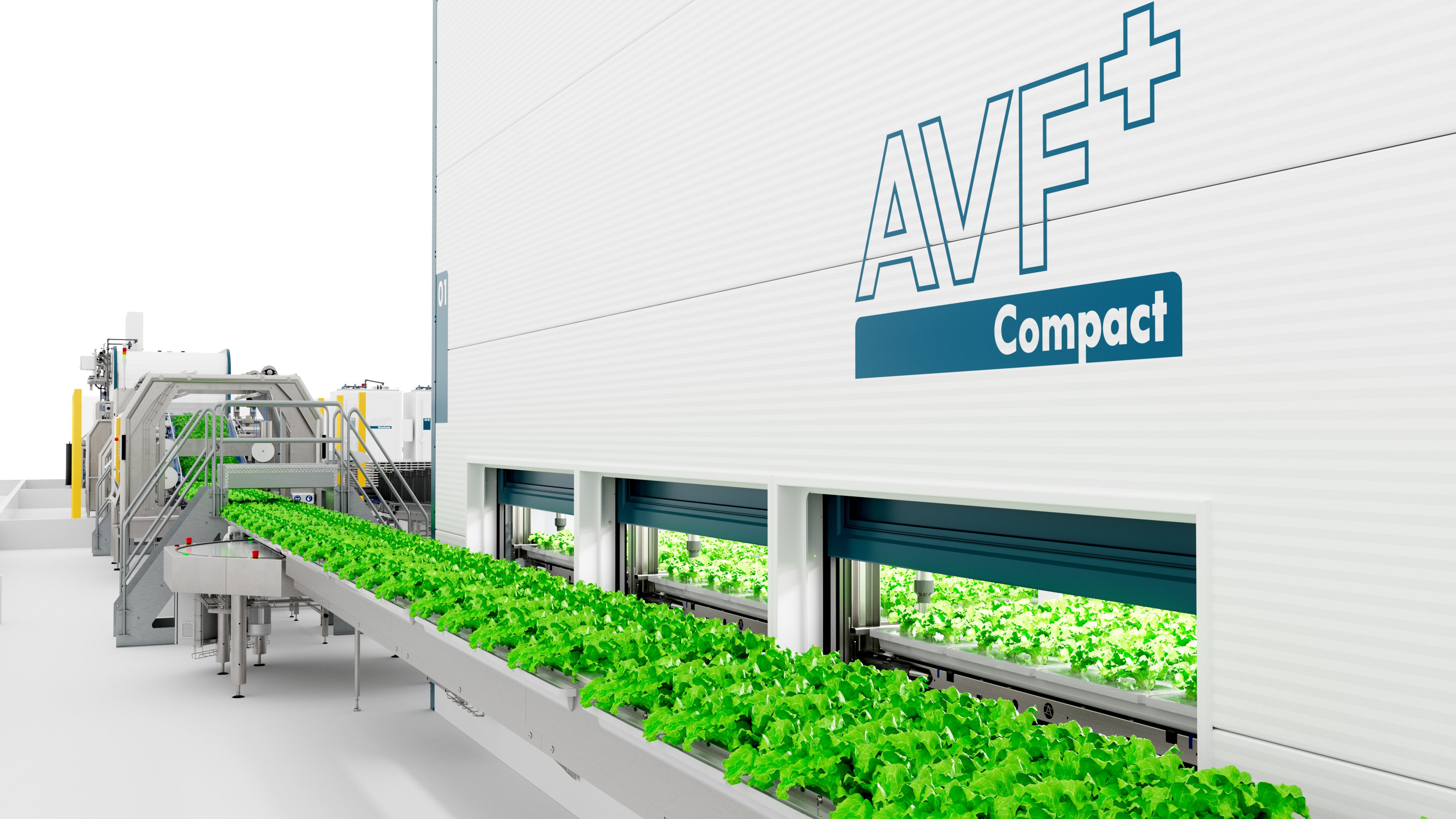

What options does Artechno Growsystems offer for automated vertical farming?

''We have four options:

- AVF+ Junior

Research and development for crop recipes. - AVF+ Compact

Medium to Large Automated Vertical Farm. - AVF+ Factory

Medium to Large Automated Vertical Farm with Processing Equipment. - AVF+ Hybrid

For propagation in an AVF+ environment, propagation in Artechno Growsystem's DFT Hydroponics or other means.

Together with our client, we analyze and calculate the best suitable option for the business case.”

How does your AVF+ Junior cell contribute to a profitable business case?

"The AVF+ Junior is, in fact, your research center. Here, the research on crops and growing recipes is conducted on a small scale until the growing recipe is perfected. Through the software, the grow recipe is imported into FarmOs, this being the software platform on which all climate cells run.

This makes it easy to implement new grow recipes in the AVF Factory.

These AVF+ Junior research climate cells allow you to analyze the operational costs per crop and use the data for your business case.

The AVF+ Junior enables you to continue developing, improving, and staying agile for the future.”

How long does the research take before you can enter the market?

"Proper research determines your future and your payback period. You can achieve results within 3 - 6 months, depending on the crop type.

If you have your own AVF+ Junior, you can sometimes enter the market after just two months of testing."

Can you guarantee that the options you offer your customer is profitable?

"Our goal is always to ensure a solid ROI results from a business case.

We examine whether you need, for instance, three or eight climate cells to make your business case profitable. We work toward that goal during the customer journey I mentioned earlier. And indeed, we guide customers to achieve their cultivation process depending on the agreements we made to ensure that they achieve the set goals.”

Can you continually scale up?

"In itself, there is no limit. You just have to deal with the automation that may have to be upgraded due to the processing volume of the farm.

The automation must be sensible and rational relative to the AVF+ Factory investment. You have to find the right balance to make any business case profitable.“

Are the possibilities with vertical farming endless?

"No, I don't think so. For example, I don't envision us growing corn or wheat in our automated vertical farms. For this, vast areas are required, which is not feasible indoors. Besides, you can perfectly grow wheat in open fields.

Other crops, such as tomatoes, peppers, cucumbers, and saffron, are vulnerable to diseases when grown in open fields. In that case, you have to use pesticides. In a vertical farm, those risks are eliminated. Various products requiring a small cultivation area will be grown increasingly in automated vertical farms.”

So it's fair to state that automated vertical farming is profitable, so why does there still seem to be doubt in the market?

"I think that has to do with reputation and trust. When you look at the reputation of vertical farming versus greenhouses, you’ll see that greenhouses are kept somewhat out of the equation.

Certainly, there are drawbacks to greenhouse operations, such as CO2 emissions and energy consumption. If you look at CO2 emissions, Vertical farming is by far the most sustainable. And yes, of course, we use energy, just like a greenhouse, but we need to ensure the perfect balance between all business case factors.

This is a new market. Investors want to see proof and figures that it works and that it is profitable. Therefore, we at Artechno Growsystems work hard to collect and share proven figures with our clients.

Vertical farming is a profitable and essential part of the horticultural sector of the future."

Click here for more information.

More news